Corroded brake lines and flare nuts have been a problem since hydraulic brakes were first installed on vehicles.

Improved materials and processes have improved serviceability, but in the Northeast and Midwest where salt and other agents are used to de-ice roads, it is still a problem.

Brake Tubing 101

Beginning in the 1930s, the Bundy Company began making tubing for the new hydraulic brake systems. Bundy tube is a double-walled low-carbon steel tube. It is manufactured by rolling a copper-coated strip and heating to 720 degrees, while the seam resistance brazed by a process called a Bundy weld.

This produces a seamless tube that can be easily flared (Figure 1). The manufacturing process is still used today. The original anti-corrosive coatings were a hot-dip lead-tin coating to both internal and external surfaces followed by zinc-rich paint applied to the exterior. Currently coatings of aluminum-zinc and polyvinyl-fluoride have improved corrosion resistance. A 1969 study by the SAE recommended the replacement of Bundy tube with 90-10 copper-nickel alloy to reduce corrosion concerns.

This produces a seamless tube that can be easily flared (Figure 1). The manufacturing process is still used today. The original anti-corrosive coatings were a hot-dip lead-tin coating to both internal and external surfaces followed by zinc-rich paint applied to the exterior. Currently coatings of aluminum-zinc and polyvinyl-fluoride have improved corrosion resistance. A 1969 study by the SAE recommended the replacement of Bundy tube with 90-10 copper-nickel alloy to reduce corrosion concerns.

The problem is the copper-nickel tubing is approximately two and a half times more expensive than the Bundy tube with corrosion protective coatings. This cost differential lends its use to premium vehicles only.

Corrosion 101

Dissimilar metal corrosion, known as Galvanic Corrosion, is a chemical process by which metals in contact with each other corrode. In order for corrosion to take place, certain conditions must be present. It requires two dissimilar metals, such as steel and brass. There must be a conductor such as contaminated water.

v Salt used to de-ice roads in cold climates is usually the most destructive water-born conductor. The contaminated water allows the metals to transfer to the conductor and form corrosion. The best visible example of corrosion is what appears around battery terminals. What happens on the outside of the brake tubing can also happen on the inside. Brake fluid is hydroscopic — that means it will absorb water and that can affect the boiling point and chemical stability. Brake fluid contains corrosion inhibitors, antioxidants and other agents to maintain chemical stability.

Brake fluid can break down like motor oil and coolant to cause corrosion to internal components. What breaks down is the active corrosion inhibitors that are present in the fluid. Also, thermal oxidation can cause chemical reactions between the fluid and rubber components contributing to further break down of the fluid. The amount of active inhibitors and water are the major factors in determining the condition of the fluid.

Brake Line Replacement

The brake lines on vehicles produced from the late 1960s to current should last from 8 to 10 years or more. Lines exposed to excessive road splash and debris can corrode and fail in a much shorter time.

Use of improper tools, such as locking pliers, can damage the surface coatings on a line or fitting that can cause the corrosion to accelerate. Corrosion between the flare nut and the tubing can cause the nut to seize on the tube. The use of a good penetrating agent can loosen the nut and prevent damage to the tubing.

There are three types of flare and flare nut used on brake tubing. The most common is the SAE 45º flare, which can have both U.S. and Metric threaded nuts. The 37º AN/JIC flare is used on many performance applications. The ISO flare can have both U.S. and Metric type flare nuts. It is referred to as the bubble flare (Figure 2).

Options for replacing a corroded or damaged brake line:

(1) Order a aftermarket source;

(2) fabricate a replacement from a universal line and fittings;

or (3) try to find a used part. Option one is the best solution if the owner can allow the vehicle to be out of service until the part can be obtained. Option two is for the vehicle that needs to be returned to service as soon as possible. This replacement depends on your ability to fabricate a reliable replacement. Option three is not recommended.

The number of times you are confronted with a damaged line will guide your decision to buy the tools or to purchase a replacement. The investment in tools to properly fabricate a universal line can range from $100 to $300. There is an old saying, “You are only as good as your tools.” The ultimate replacement is copper-nickel or stainless steel, but cost and availability are a factor.

Brake Hose Replacement

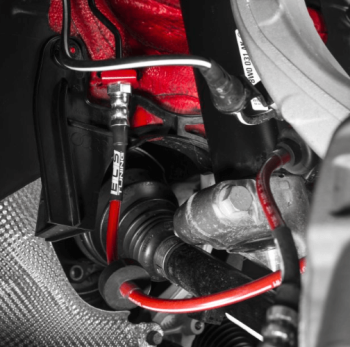

Factors that contribute to the deterioration of rubber brake hoses include: High ambient temperatures and ozone that cause the cover and fabric to deteriorate. Moisture absorption through the hose can contaminate the brake fluid. Break down of brake fluid can cause  contaminates that can swell the tube and restrict flow. Caliper hoses can be twisted or stressed during pad replacement. It usually causes damage to the tube and fabric of the hose. This damage can result in a restriction and ultimate failure of the hose (Figure 3). Over flexing caused by improperly installed lift kits can cause damage to the tube and fabric. Lift kits can require that brake hoses be replaced to compensate for the change in suspension height.

contaminates that can swell the tube and restrict flow. Caliper hoses can be twisted or stressed during pad replacement. It usually causes damage to the tube and fabric of the hose. This damage can result in a restriction and ultimate failure of the hose (Figure 3). Over flexing caused by improperly installed lift kits can cause damage to the tube and fabric. Lift kits can require that brake hoses be replaced to compensate for the change in suspension height.

Brake Fluid 101

The Department of Transportation (DOT) Federal Motor Vehicle Safety Standards FMVSS116 sets the performance standards for brake fluid. It does not define chemical formulation. There are three performance standards for brake fluid DOT3, DOT4 and DOT5. These standards deal primarily with the dry and wet boiling point of the fluid. The following table describes the most used base chemical composition and boiling points of the fluids:

The boiling point is a concern in the case of high ambient temperatures and heavy brake applications. Low ambient temperatures are also a concern.

As the temperature decreases, the viscosity of the fluid increases. Moisture also is a contributing factor to the change viscosity at low temperatures. This is especially important for ABS and traction control. A sluggish ABS solenoid valve could cause an increase in stopping distances.

Brake Fluid Replacement

Brake fluid needs to be replaced because time, the environment and the replacement of components can affect chemical stability of the fluid and rubber products.

Corrosion inhibitors and antioxidants are designed to treat and protect the internal surfaces of the system. Inhibitors are depleted over a period of time and cannot offer protection to new components installed in a system while the existing surfaces may still have some protection. The depleted corrosion inhibitors can offer little or no protection for the new component. Another problem is particulate material generated by oxidation and corrosion. The copper and other particulates can collect in ABS solenoids and motor valves causing them to malfunction. A thorough brake system flush is recommended to protect the new parts.

Brake fluid should be tested at least once a year. Some manufacturers have recommended fluid change intervals. Check your service information source or the owner’s manual.

There are test strips and instruments that can be used to test brake fluid. These strips measure the copper particle concentration. This is an indicator of the condition of the corrosion inhibitors in the brake fluid. The test can be made at the master cylinder. The first concern is particulate contamination, especially on ABS equipped vehicles. Dislodged particles can block a passage and or prevent a valve from seating. The system should be flushed before replacing an ABS valve and motor assembly to prevent any contaminates from entering the new component. Whether you push or pull the fluid through the system depends on what works the best for a given vehicle. Flushing and replacing the fluid can prevent future repairs.

Today’s vehicles are lasting longer than those produced in the 90s. Preventive maintenance, such as flushing and replacing the brake fluid, can lower future repair costs.