SAE Flange L.T.

|

|

|

|

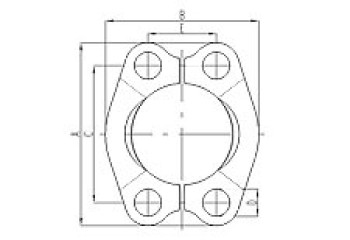

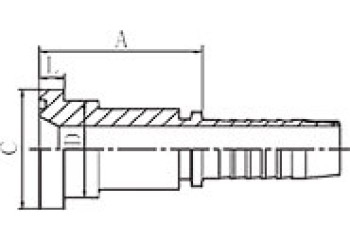

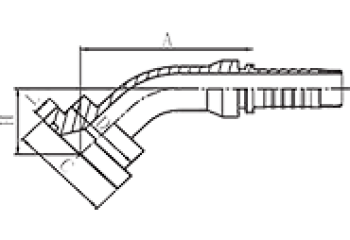

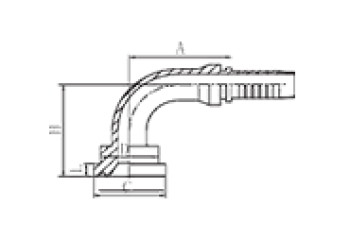

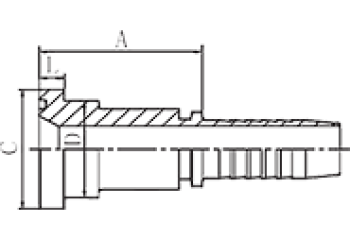

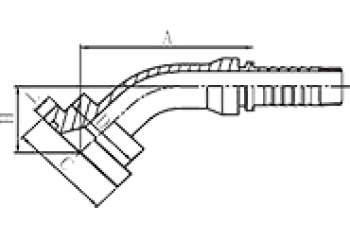

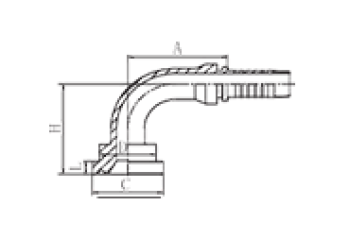

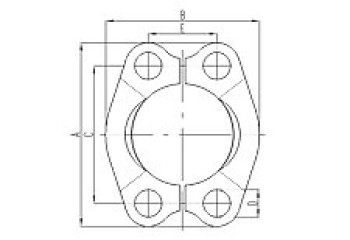

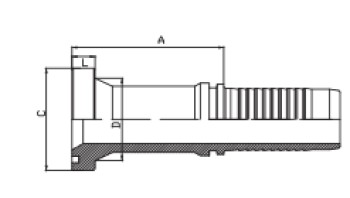

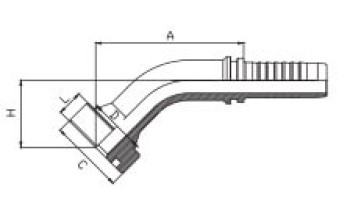

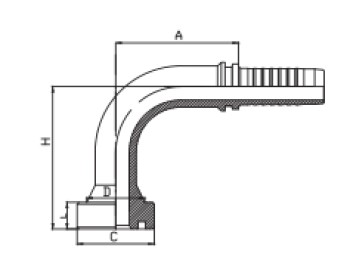

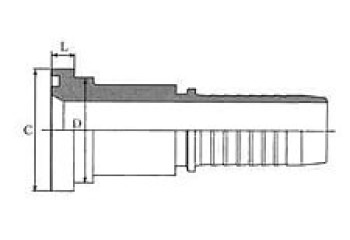

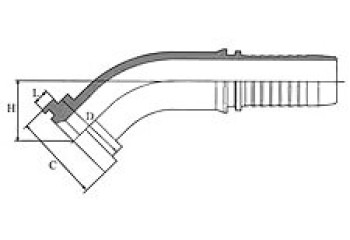

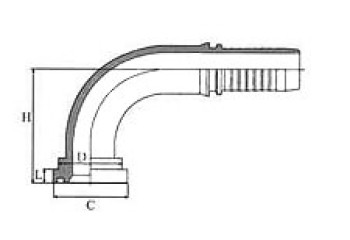

| SAE SPLIT FLANGE CLAMP 3000PSI | SAE Flange 3000psi | 45° SAE FLANGE 3000PSI | 90° SAE FLANGE 3000PSI |

FL | 87311/87312 | 87341/87342 | 87391/87392 |

SAE Flange H.T.

|

|

|

|

SAE FLANGE 6000PSI | 45º SAE FLANGE 6000PSI | 90º SAE FLANGE 6000PSI | SAE SPLIT FLANGE CLAMPS 6000PSI |

| 87611/87612 | 87641/87642 | 87691/87692 | FS |

|

|

| |

| SAE FLANGE 9000PSI | 45º SAE FLANGE 9000PSI | 90º SAE FLANGE 9000PSI | |

| 87911/87912 | 87941/87942 | 87991/87992 |

JIS Flange

|

|

|

| JIS FLANGE | 45º JIS FLANGE | 90º JIS FLANGE |

88111/88112 | 88141/88142 | 88191/88192 |

How to order Hose Fitting

How to Read the Fittings

26711DY-06-04SS - Fitting Type (1=Male, 2=Female, 5=Metric Standpipe, 7=Banjo, 8=Flange)

26711DY-06-04SS - End Connection (1=METRIC, 2=BSP, 3=BSPT, 4=ORFS, 5=NPT, 6=JIC, 7=SAE, 8=JIS METRIC, 9=JIS GAS)

26711DY-06-04SS - Seal Type (1=Multi Seal, 2=Flat Seal , 3=Flat Seal with O-ring, 4=24° O-ring Cone Seal, Light Series,

5=24° O-ring Cone Seal, Heavy Series, 6=60° Cone Seal, 7=37° Cone Seal, 8=90° Cone Seal;

For flanges, 3=3,000 PSI, Code 61, 6=6,000 PSI, Code 62, 9=9,000 PSI, Caterpillar Series)

26711DY-06-04SS - Fitting Shape (1=Straight, 4=45 Degree Elbow, 9=90 Degree Elbow)

26711DY-06-04SS - Hose Application (1=For One or Two Wire Braided Hose,

2=For Four Wire Spiral Hose,

3=For Six Wire Spiral Hose)

26711DY-06-04SS - Hexagon (No Suffix=Single Hexagon, D=Double Hexagon)

26711DY-06-04SS - Fitting Type (No Suffix=Two Piece Series Fitting, Y=One Piece Fitting Series)

26711DY-06-04SS - Size of Fitting End Connection

26711DY-06-04SS - Hose Size

26711DY-06-04SS - Fitting Material (No Suffix=Carbon Steel, B=Brass, SS=Stainless Steel)

| MATERIAL | CARBON STEEL | COPPER | STAINLESS STEEL |

| SIGN | BR | SS |

| HOSE DN | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 25 | 32 | 40 | 45 | 50 | 64 |

| HOSE DASH | -01 | -02 | -03 | -04 | -05 | -06 | -08 | -10 | -12 | -16 | -20 | -24 | -28 | -32 | -40 |

| HOSE DASH | 02 | 04 | 05 | 06 | 08 | 10 | 12 | 16 | 20 | 24 | 32 |

| BSP THREAD | G1/8"×28 | G1/4"×19 | G3/8"×19 | G1/2"×14 | G5/8"×14 | G3/4"×14 | G1"×11 | G1.1/4"×11 | G1.1/2"×11 | G2"×11 | |

| BSPT THREAD | R1/8"×28 | R1/4"×19 | R3/8"×19 | R1/2"×14 | R3/4"×14 | R1"×11 | R1.1/4"×11 | R1.1/2"×11 | R2"×11 | ||

| NPT THREAD | Z1/8"x27 | Z1/4"×18 | Z3/8"×18 | Z1/2"×14 | Z3/4"×14 | Z1"×11.5 | Z1.1/4"×11.5 | Z1.1/2"×11.5 | Z2"×11.5 | ||

| JIC THREAD | 7/16"×20 | 1/2"×20 | 9/16"×18 | 3/4"×16 | 7/8"×14 | 1.1/16"×12 | 1.5/15"×12 | 1.5/8"×12 | 1.7/8"×12 | 2.1/2"×12 | |

FLANGE SIZE | 1/2" | 3/4" | 1" | 1.1/4" | 1.1/2" | 2" |

Hydraulic hose fittings are necessary when connect various conductors such as tubes, pipes, and hydraulic hoses in the hydraulic system. Most of connections pipe fittings have a male and female component to accommodate the connection and assist with the process of containing and directing the flow of fluid. Also it can prevent any leakages and maintain pressure in the hydraulic system. Consequently, hydraulic fittings need to be strong, versatile, and reliable to operate safely and effectively in their respective applications. So hose fittings typically adhere to strict standards which dictate fitting construction, dimensions, and pressure ratings. Our jinchi fitting factory are hose supplier and supplier different hydraulic fitting types(custom fitting, flare fittings,JIC fittings, NPT fitting, parker hydraulic fittings, push lock fittings, flared fitting, BSPP fittings, metric hydraulic fittings, bsp fitting, ptfe fitting, stainless steel fittings, SAE fittings, reusable hydraulic hose fitting, swivel pipe fitting).

Types of Fittings

1. Connection Type Fittings

Hydraulic fittings are attached via a number of different connection methods, each with its own conveniences and advantages.

2. Compression Fittings

Compression fittings include all types of fittings which use compressive force to connect the vessel to the fitting.

1)Standard compression fittings use metal gaskets, rings, or ferrules which form a seal on the vessel through compression. The compression is typically made by tightening a nut onto the fitting over the piping and ferrule, compressing, and securing the vessel inside. Standard compression fittings do not require tools to assemble, making them convenient for quick field installations.

2)Bite-type fittings are compressive fittings with a sharpened ferrule that "bites" the vessel when compressed and provides the seal. Bite-type fittings, like standard compressive fittings, require no special tools to assemble, but provide a stronger, higher pressure connection.

3)Flare fittings consist of a body with a flared or coned end. Special flaring tools are used to install the vessel inside the flared end, providing a deep seal. Flare fittings can handle higher pressures and a wider range of operating parameters than standard compression fittings.

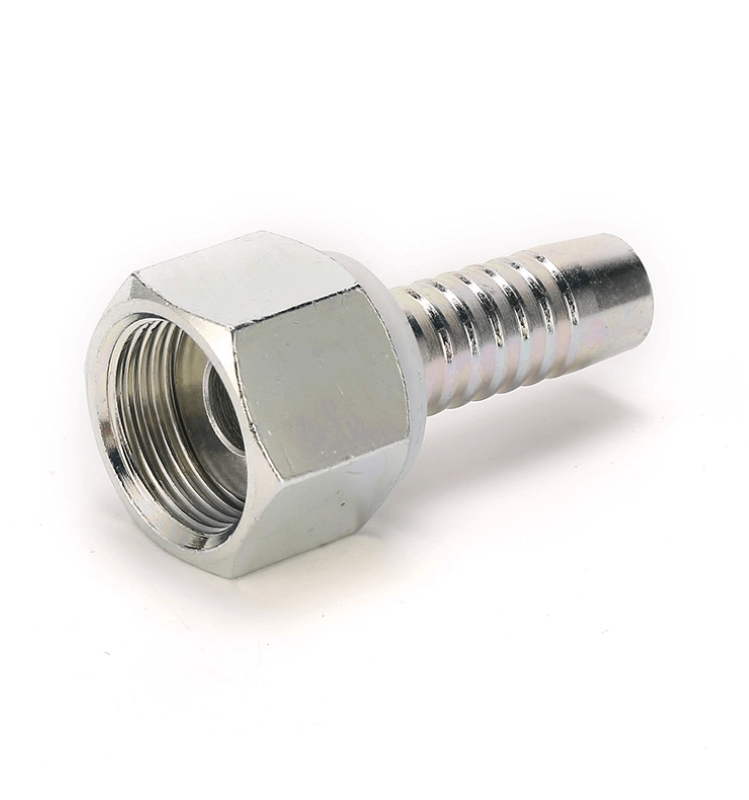

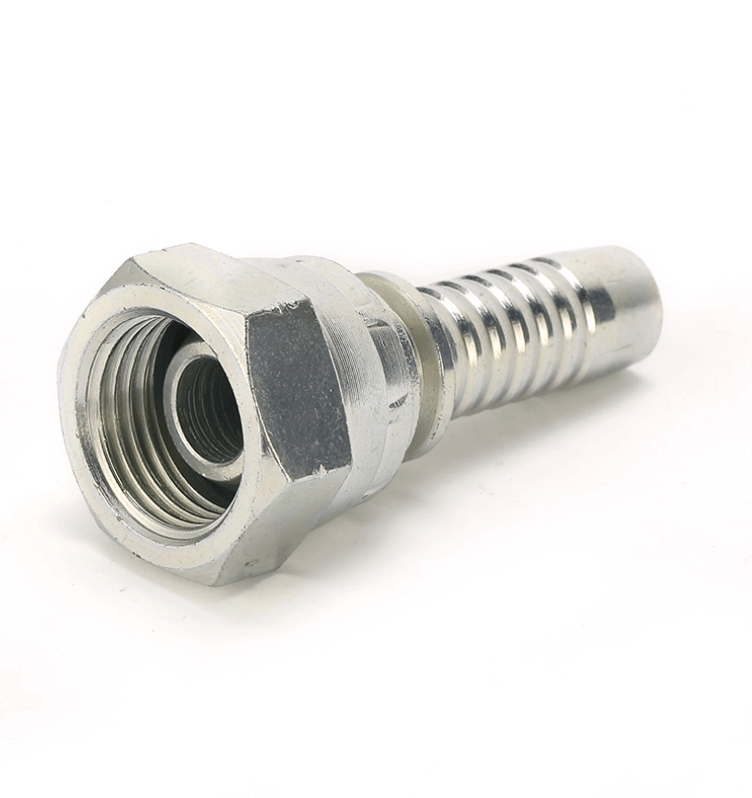

3.Crimp Fittings

Crimp fittings involve placing hose over a tubular end and crimping against it with a sleeve, ring, or crimp socket. These fittings typically require crimping tools or machines to make the connections.

4.End Fittings

End fittings provide specific surfaces for connecting vessels in hydraulic systems. Plain ends are fittings with surfaces which allow pipes or tubes to be connected by adhesive, solder, welding, or other permanent means. Welding, when done properly on compatible materials, provides a strong and reliable connection.

5.Flange Fittings

Flange fittings are rims, edges, ribs, or collars with flush surfaces perpendicular to the attached pipe or tube. These surfaces are joined and sealed via clamps, bolts, welding, brazing, and/or threading.

6.Push-to-Connect

Push-to-connect fittings have ends that are designed to accept tubing by pushing it into the end. These fittings typically disconnect via some type of collar retraction. These connections are convenient for sections of the system requiring frequent disconnection and reconnection.

7.Threaded Fittings

Threaded fittings have screw threads (built-in grooves) on their inner (female) or outer (male) surfaces designed to accept connections with matching threads. Threads which provide a simple connection but no seal are called straight threads. Tapered threads are designed to provide a tight seal for gases or fluids under pressure. Seal reliability can be improved by adding a coating or seal tape (Teflon). Especially precise threads are called "dry fit", meaning they seal without the need for an additional sealant, which is important in applications where sealant addition could cause contamination or corrosion. The thread size is measured and based on the inside of the vessel. Thread size standards include NPT (National Pipe Thread) and BSP (British Standard Pipe), though other standards exist and usage often varies by country and industry. Each standard corresponds to a particular number of threads per inch (TPI).

Gallery